Fibre laser cutting provides clean cuts in sheet and tube metal workpieces, with speed, precision, and cost efficiency. This advanced technology is increasingly popular for manufacturing and fabrication in sectors including automotive, aerospace, and construction. When used correctly, they are cleaner, faster, and reduce material wastage.

Whether you’re a small workshop looking to modernise or a large-scale manufacturer seeking to streamline production, understanding how fibre laser technology works—and what it can do—can help you make smarter, more profitable decisions.

In this guide, we cover everything from how fibre laser cutting works to key benefits, materials compatibility, operational tips, and maintenance best practices.

How Fibre Laser Cutting Works

A fibre laser cutting machine uses a concentrated beam of light, generated through fibre-optic technology, to vaporise metal along a path with extraordinary precision.

- 1Laser Generation A high-powered laser beam is produced within a fibre-optic cable containing with rare-earth elements like ytterbium.

- 2Beam Focusing Mirrors and lenses focus the beam to a fine point, generating temperatures over 1,000°C at the material surface.

- 3Material Cutting The intense heat melts or vaporises the metal.

- 4Assist Gas High-pressure gases (nitrogen, oxygen, or air) blow away molten metal, leaving clean, burr-free edges.

- 5Computer Control CNC software guides the laser head across the material, enabling high-speed, complex, and repeatable cuts.

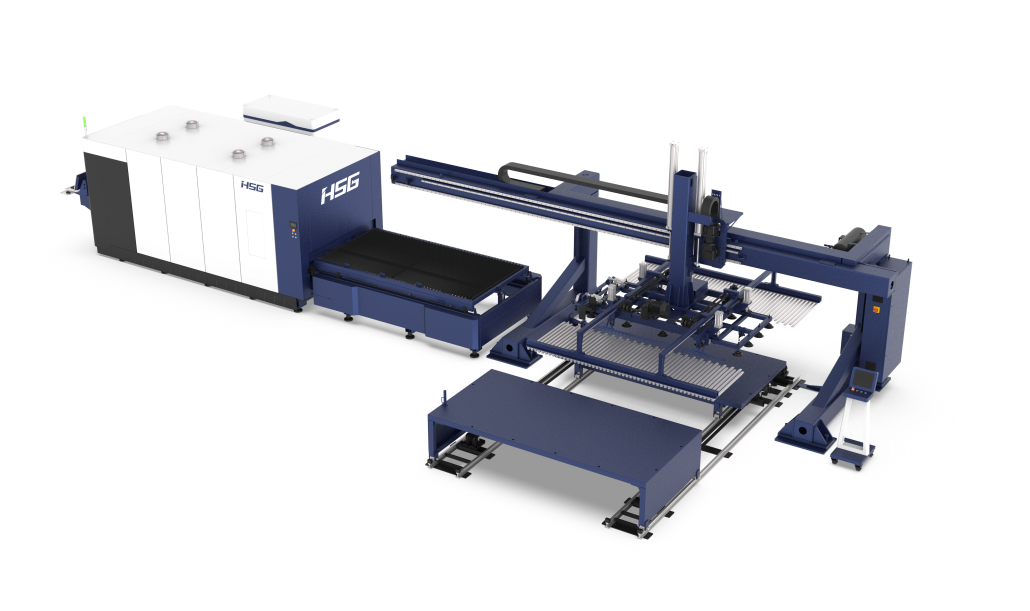

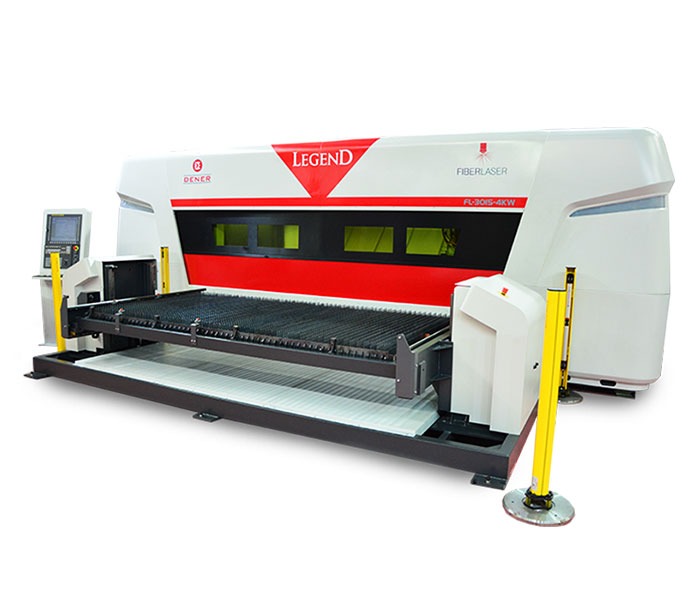

MTL Engineering supplies state-of-the-art machines from trusted brands like Dener and HSG, known for reliability and advanced control systems.

Key Benefits Over Other Technologies

Fibre lasers outperform traditional CO₂ and plasma cutting systems in several critical ways:

- High Precision: Tolerances as tight as ±0.1 mm.

- Non-Contact Process: Reduces wear and part deformation.

- Energy Efficient: Up to 50% more efficient than CO₂ lasers.

- Low Maintenance: Fewer consumables, no mirrors, and solid-state components.

- High Uptime: Long service life and minimal downtime.

- Automation Friendly: Easily integrates with smart manufacturing systems.

These advantages make fibre lasers ideal for 24/7 production environments.

What Materials and Thicknesses Can Be Cut

Fibre lasers are compatible with a wide range of metals. Below is a guide to typical thickness capabilities and optimal assist gases:

| Material | Max Thickness (Typical) | Optimal Assist Gas | Notes |

| Mild Steel | Up to 25 mm | Oxygen / Air | Clean, high-speed cuts; air can reduce costs for thinner sections |

| Stainless Steel | Up to 20 mm | Nitrogen | Smooth, oxidation-free edges; food-grade suitable |

| Aluminium | Up to 15 mm | Nitrogen | Requires clean gas for burr-free edges |

| Copper & Brass | Up to 10 mm | Nitrogen | Efficient cutting of reflective metals |

| Titanium | Varies by machine power | Nitrogen | Widely used in aerospace and medical industries |

How to Operate a Fibre Laser Cutter

1. Prepare the machine

Power up the system and check the cooling system is ready. Clean the lens, check for debris, and make sure the laser head is properly aligned. Verify the homing position from the interface. Inspect nozzles to check whether they need replacing.

2. Load your design file

You’ll need to use CAM software to convert design files (usually a DXF or DWG) into G-code that the machine can read. Upload the file into the machine control system.

3. Set the cutting parameters

3: Set the cutting parameters.

Fibre lasers need proper setup to deliver clean, precise cuts. Choose Paramaters most suitable for the material and the design complexity.

Choose a power level that will cut through material quickly, but lower it when using material with a lower burn point such as stainless steel.

Balance cutting speed against thickness to ensure a complete cut. Thicker workpieces/denser materials need slower speeds. You should also reduce speed by 10-15% for tight tolerances as faster cutting is less accurate.

Select a higher pulse frequency for thin sheets of stainless steel to prevent material burn, while a lower frequency is better for thicker steel to minimise the heat-affected zone.

Set the focus distance slightly below the surface of the material. Setting it too high or too low can lead to burring and burns.

- For carbon steel under 4mm thick, set the focus distance at 0mm (the narrowest point of the laser is on the surface.)

- For stainless steel or aluminium thinner than 2mm, a focus distance of -1mm will provide cleaner edges.

Test your settings on scrap material before you run the program.

Expert Cutting Tips & Best Practices

For small parts—especially under 50mm—use micro-joints. These are tiny tabs that hold the piece in place during cutting, so it doesn’t tip or move. This prevents damage to both the part and the laser head.

The focus point of the laser should sit right at or slightly below the surface of the material. If it’s too high or too low, you’ll see burrs or burnt edges. For carbon steel under 4mm, aim for a focus height of 0mm. For thin stainless or aluminium, go slightly below—around -1mm.

Keep the nozzle height steady too. Most materials cut well with a 0.8 to 1.2mm gap. Using automatic height control helps keep things consistent.

You can also save time and materials with nesting software. It arranges your parts efficiently across the sheet, reducing waste. For parts that need high accuracy, slow the speed down by 10–15% to prevent thermal distortion.

Maintenance & Performance Tips

Consistent upkeep extends machine life and ensures cut quality. Make these maintenance practices habitual and display them clearly around your machinery to keep all operators informed.

Daily

Clean the lens and nozzle daily. Check that the gas supply is clean and at the right pressure. Clear out any slag buildup from the cutting bed.

Weekly

Vacuum dust from internal components and check safety interlocks. Make sure electrical cabinets are sealed and guide rails are clear and lubricated.

Quarterly

Calibrate the laser head and check that the tracks are aligned and straight. Even small misalignments can affect cut quality. A loose tension strip might seem minor—but it can be dangerous and lead to machine damage or injury.

Advanced Features & Automation

Fibre Laser Cutting Machines in MTL Engineering’s range are equipped with advanced features which can streamline your fabrication processes.

- Automatic Gas Selection Systems

- Automatic Sheet Measurement Vision Systems

- Intelligent Path Optimisations

- Nesting Software To Minimise Material Wastes

- Automatic Loading and Unloading

These features streamline operations and increase throughput, giving a new fibre laser cutting machine a great return on investment.

Choosing the Right Machine

The right machine depends on your material type, workflow, and budget.

Sheet Cutting

Tube Cutting

Considerations:

- Bed size

- Laser power (1kW–15kW)

- Software ease of use

- Local support and service

- Energy and operating costs

- New vs refurbished machines

Need help? MTL Engineering has over 23 years’ experience in CNC machinery. Our engineers provide expert consultation, installation, and training for every machine we sell.

Safety & Environmental Considerations

Always use proper enclosures to protect operators from laser exposure. Ventilation is a must, especially when cutting oily or coated materials. Match your assist gas to the material to reduce rework and improve safety.

Scrap should be separated and disposed of properly. Clean, recycled metal has value—and reduces your environmental impact.

A Comprehensive Guide

Fibre laser cutting is essential to keeping fabrication businesses ahead of the curve:

- Exceptionally Accurate: ±0.1mm tolerances

- Quick Fabrication: Cuts faster than CO₂ or plasma systems

- Low Maintenance: Solid-state reliability

- Cost-Effective: Energy efficient, with fewer consumables

- Smart Integration: Compatible with automated workflows

2026 © MTL Engineering Ltd

All Rights Reserved | Design by eSterling